-

中文全称:玻璃纤维增强水泥复合材料

英文名:Glass-fiber Reinforced Cement

GRC 是玻璃纤维增强水泥复合材料的英文缩写,来源于欧美技术,是将抗碱玻璃纤维、水泥、砂等其他复合材料按一定配比搅拌,在模具 内浇灌成型,生产出造型丰富,质感多样的产品,被广泛应用在国内 外各具特色的建筑中。

GRC 的胶凝材料是水泥,所以 GRC 也是一种混 凝土制品,属于混凝土行业中的一个分支。普通的混凝土抗压强度很 高,但是抗弯强度、抗拉强度以及抗冲击强度却较低。GRC 由于其中 掺入了抗碱玻璃纤维,使得其在以上的各方面性能相比于普通的混凝 土有了质的飞跃,在不降低混凝土制品本身优势的情况下,GRC 材料 大幅提高了水泥制品的抗弯强度、抗拉强度、抗冲击强度并降低了自 身的密度。

优质的 GRC 制品的抗弯强度可以达到 25Mpa,抗冲击强度 达到 10-25KJ/m2,但是其干密度只有 1800-2000kg/m3,要比混凝土 制品轻 1/5 左右。以上这些特点使得 GRC 相比于预制混凝土或其他水 泥制品的有着非常明显的优势,尤其是当需要薄壁型的材料时,其抗 弯、抗冲击强度的优势将更加明显。

GRC应该领域

GRC建筑细部装饰构件,简称:GRC建筑细部。GRC幕墙板,或称:GRC外墙挂板。GRC园林景观制品,如:GRC雕塑,GRC假山,GRC小品,GRC花钵等。还有GRC轻质隔墙板、GRC保温板、通风管道、永久性管状芯模、永久性模板、工业建筑屋面构件、声屏障、自承载式地板、灌溉渠道等。

-

GRC设计的基础规定

GRC design basis一、GRC外墙装饰构件的设计工作

1.建筑立面设计(即构件应用设计)。

2.构件与建筑物连接节点设计。

3.构件设计。

GRC外墙装饰构件的设计和应用设计必须符合国家有关的建筑与结构的规范要求。建筑立面设计与构件选用

First, GRC exterior wall decoration components of the design work

1. Building facade design (ie, component design).

2. Component and building connection node design.

3. Component design.

GRC exterior wall design and application design must comply with the relevant national building and structural specifications. Building facade design and component selection

二、GRC外墙装饰构件的建筑立面设计要求

1.满足建筑物使用功能的要求。

2.与建筑物所在环境协调。

3.美观、和谐、风格统一。

4.比例正确、尺度合适。

5.技术可行、安装方便。

6.经济合理。

Second, GRC exterior decorative components of the building facade design requirements

1. Meet the requirements of building use function.

2. Coordinate with the environment in which the building is located.

3. beautiful, harmonious, style unity.

4. The ratio is correct and the scale is appropriate.

5. Technology is feasible and easy to install.

6. Economical and reasonable.

三、构件应用设计须给出详细的施工图、节点图

1.构件类型、品种、规格、质感、颜色。

2.构件使用的部位与数量。

3.构件的组合排列与接缝方式。

4.构件的收口处理。

Third, the application of components to be given a detailed design drawings, node map

1. Component type, variety, size, texture, color.

2. The number and number of parts used.

3. Combination of components and seams way.

4. Component of the mouth closed processing.

四、横向连续构件(如檐线、腰线)与转角处的处理方式

1.确定构件连接处缝隙。考虑到干湿变形和温度变形因素,水平连续构件之 间必须留有伸缩缝。单根长度不大于2m的构件其伸缩缝宽不小于5mm。单根长度2m以上的构件,伸缩缝宽应为5—10mm。

2.构件间缝隙处理的方式有三种:

(1)明缝。类似真石材构件,保持自然接缝效果。

(2)半明缝。用橡胶条(或塑料条)塞缝,建筑密封胶嵌缝。

(3)暗缝。用橡胶条(或塑料条)塞缝,建筑密封胶嵌缝后刮腻子,刷涂料, 使接缝处与构件表面一致。备注:半明缝和暗缝处理时不得使用水泥砂浆嵌缝。

3.必须根据建筑物轴线尺寸、门窗洞位置、墙体转角变化情况和墙体伸缩缝(沉降缝)的位置等因素来确定每个构件的长度,使构件的连接缝位置与建筑物立面统一协调对称。且构件的大小适于制做与安装。水平构件长度范围可在1.2—2.4m之间。

4.建筑物转角处的水平构件须设计成阴阳角构件,不得使用构件切割拼接。阴阳角单边长度可在0.3—1.2m之间。

Fourth, horizontal continuous components (such as eaves line, waist line) and the corner of the treatment

1. Determine the gap at the component connection.Taking into account the wet and dry deformation and temperature deformation factors, horizontal continuous components must be between the expansion joints.Single length of not more than 2m of the components of its expansion joints width of not less than 5mm. Single length of more than 2m components, expansion joints should be 5-10mm wide.

2.There are three ways of gap handling between components:

(1) clear seam. Similar to the real stone components, to maintain the natural seam effect.

(2) half clear seam. With rubber strips (or plastic strips) seams, building sealant caulks.

(3) dark seam. With rubber strips (or plastic strips) seams, building sealant caulking after scraping putty, brush paint, so that the seams and components on the same surface.

(Note: semi-clear seam and dark seam treatment should not use cement mortar caulking.)

3. The length of each component must be determined by the factors such as the size of the building's axis, the position of the door and window, the change of the corner of the wall and the position of the wall expansion joint (settlement slit), so that the connecting seam position of the component and the building facade Harmonized symmetrical symmetry.And the size of the component is suitable for making and installing. Horizontal component length range can be between 1.2-2.4m.

4. The horizontal members at the corner of the building shall be designed as male and female corners and shall not be used for splicing. The length of the yin and yang angle can be between 0.3-1.2m.

五、纵向连续构件(如柱、竖向线套等)的长度、接缝方式。

1.根据立面效果要求、结构条件和制造、运输、安装构件的条件确定纵向连续构件每段构件的长度。纵向构件单根长度一般可在1.2—3.6m之间。直径大于800的柱子如运输安装具备条件,也可做成5—6m长,以避免或减少裂缝。

2.纵向连续构件连接处的缝隙宽度与处理方式与水平连续构件相同。

3.纵向连续构件的分段设计应避免将上层构件的重量传递给下层构件。

4.纵向构件不能跨伸缩缝(沉降缝)设置。

Fifth, the length of continuous continuous components (such as columns, vertical sets, etc.) length, seam way.

1. Determine the length of each component of the longitudinal continuous member according to the conditions of the facade, the structural conditions and the conditions of manufacture, transportation and installation. The longitudinal length of a single member is generally between 1.2 and 3.6 m. A column with a diameter greater than 800, such as a transport installation, can also be made to 5-6 m long to avoid or reduce cracks.

2. The width of the slit longitudinally continuous handling member connected at the same horizontal continuous member.

3. The longitudinal design of the longitudinal continuous member shall avoid the transmission of the weight of the upper layer member to the lower member.

4. The longitudinal members can not be set across the expansion joints (settling joints).

六、组合构件(如门窗套、组合山花、由柱与线脚组成的柱廊等)应保证构件间的比例关系合适,逻辑关系合理,接缝处理可与水平连续构件相同。平面连续构件(如山泰石、连续铺设的装饰板等)须根据建筑立面的详细尺寸绘制构件排列图,确定构件的横缝竖缝的位置与缝宽(缝宽可选10—30mm)。计算因错缝和收口所需要的非规则构件的详细尺寸与数量,以避免现场剪裁切割构件。平面连续构件在建筑物伸缩缝(沉降缝)处须断开。

Six, the combination of components(Such as the door and window sets, the combination of mountain flowers, columns and feet from the composition of the colonnade, etc.) should ensure that the proportion between the components of the appropriate relationship between the logical relationship is reasonable, seam processing can be the same with the horizontal continuous components.Flat continuous components (such as mountain tai stone, continuous laying of the decorative panels, etc.) shall be based on the detailed dimensions of the building facade drawing components to determine the structure of the transverse joints of the joints and the width of the joints (slot width optional 10-30mm).Calculate the detailed size and quantity of the irregularities required for stitching and closing, so as to avoid cutting the cutting members on site. The planar continuous member shall be disconnected at the building expansion joint (sinker).

七、构件与墙体的连接

1.构件与墙面连接。

(1)无防水要求,可用水泥砂浆填抹。

(2)有防水要求,须用建筑密封胶嵌缝或其它防水材料处理。

2.构件与墙体变化处的连接处(如檐口、窗口、门口、阳台、雨蓬、落水口、墙面突变处和转角处)应根据实际情况设计详细节点。在边缘部位要特别注意安装螺栓将墙体劈开的可能性,因此,构件的位置确定须保证安装螺栓距边缘有一定的距离。

3.落水管、外挂设备(如空调机)与构件的关系。

Seven, the connection of components and walls

1. The component is connected to the wall.(1) no waterproof requirements, available cement mortar to fill.(2) there are waterproof requirements, to be used to seal the seal or other waterproof material.

2. The connection between the component and the wall change (such as cornice, window, door, balcony, rain Peng, water outlet, wall mutations and corners) should be based on the actual design of detailed nodes. In the edge of the site to pay special attention to the installation of bolts to split the possibility of the wall, so the location of the components to ensure that the installation of the bolt from the edge to ensure a certain distance.

3. The relationship between falling water pipes, plug-in equipment (such as air conditioners) and components.

八、突出墙面有积水可能的构件应考虑排水坡度。骑墙构件可排向屋面,附墙构件应排向墙外,构件顶面排水坡度应不少于3%。对于加气混凝土、空心砌块、轻质墙板和空心砖等轻质墙基体和旧建筑已经酥松或空鼓的墙体,设计立面和选用构件必须考虑墙体结构的安全性与可靠性,做出相应的结构设计与处理方案。

Eight, highlight the wall with water may be the components of the drainage should consider the slope.

The wall members can be routed to the roof, with wall members should be discharged to the wall, the top surface drainage slope should be not less than 3%.For aerated concrete, hollow blocks, lightweight wall panels and hollow bricks and other lightweight walls and old buildings have been crisp or hollowed out of the wall, the design facade and optional components must consider the wall structure of the safety and reliability, To make the corresponding structural design and treatment program.

-

GRC生产工艺

GRC production processGRC生产工艺流程主要有以下六大步:

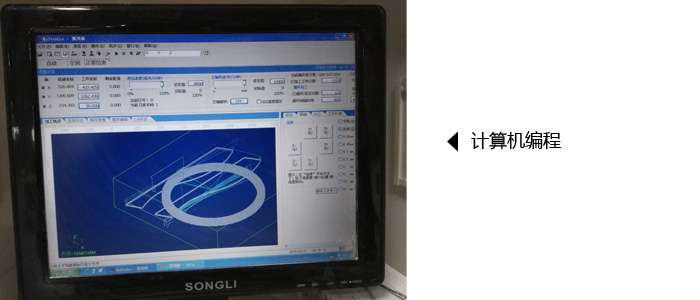

1.计算机编程

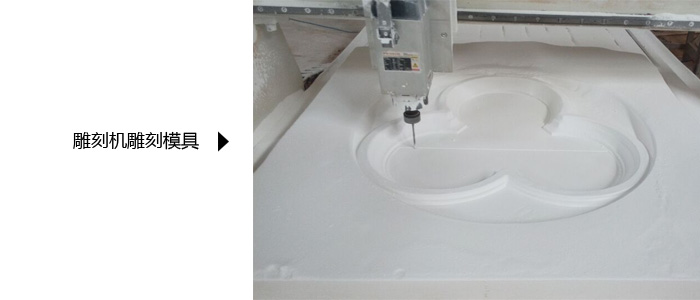

2.雕刻机雕刻模具

3.模具的组装制作

4.产品的喷射制作

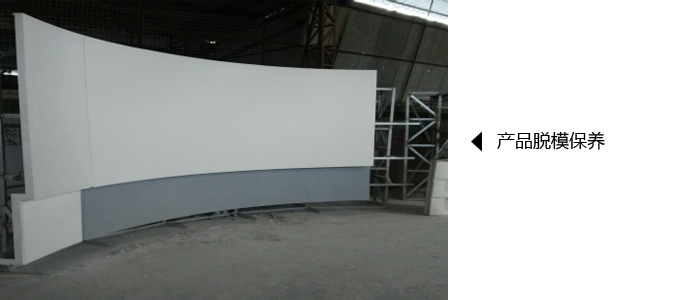

5.产品脱模保养

6.产品包装运输

GRC production process mainly has the following six steps :

1. computer programming

2.Engraving machine engraving mold

3. Mold assembly production

4. Production of the product

5. Product stripping maintenance

6. Product packaging transport

一、计算机编程:工厂的雕刻师傅根据CAD图纸,按照客户的要求和图纸上面标注的尺寸,进行编写计算机程序。需要雕刻的一般都是有造型的部位,不能使用平板来实现的部位。

一、Computer Programming:Factory carving master according to CAD drawings, in accordance with the requirements of customers and drawings marked above the size of the preparation of computer programs.Need to carve the general are the shape of the site, can not use the plate to achieve the site.

二、雕刻机雕刻模具:雕刻师把编写好的程序输入计算机,三维数控雕刻机就开始自动雕刻模具。一般雕刻的材料主要有木材、石膏、泡沫。

二、Engraving machine engraving mold : The engraver to write a good program into the computer, three-dimensional CNC engraving machine began to automatically engrave the mold.General carving materials are mainly wood, gypsum, foam.

三、模具组装制作

模具制作的基本流程如下:

1.放线---

2.开料---

3.订底台---

4.补灰打模、喷漆---

5.装订---

6.交QC检货---

三、Mold assembly production

The basic process of mold making is as follows :

1.Line---

2.Open material---

3.Set the table---

4.Fill ash mold, paint---

5.Binding---

6.To QC ---

四、模具的种类:

1.木模---使用次数多,可直接做木负模(使用20-50次)

2. 硅胶模---造价贵,主要用于雕花,不易脱模(使用20-30次)

3.玻璃钢模---使用次数多,造价比木模贵(使用100-200次)

4.石膏模---使用次数少(使用2-3次)

5.水泥模

四、The type of mold:

1. Wood mold --- the number of use, can be directly made of wood negative mold (using 20-50 times)

2. Silicone mold --- cost expensive, mainly used for carving, easy stripping (using 20-30 times)

3. FRP --- the use of more than the cost of wood than your (use 100-200 times)

4. Gypsum mold --- use less (use 2-3 times)

5. Cement mold

五、产品喷射制作:GRC的制作工艺主要有两种,一种是手糊工艺,另外一种是喷射工艺。我司制作的所有的产品,全部是喷射工艺制作。喷射工艺是GRC行业标准指定的制作工艺。喷射工艺制作出来的产品的质量和强度都是手糊工艺的几倍甚至几十倍以上。

喷射工艺的主要步骤如下:

1.清理模具---

2.打脱模油---

3.开料---

4.喷制---

5.背部收光---

五、Product jet production : GRC produ ction process there are two, one is the hand paste process, the other is the spray process.I produced all the products, all of the spray process production.The spray process is the GRC industry standard designation process.The quality and strength of the products produced by the spray process are several times or even several times more than the hand-paste process.

The main steps of the spray process are as follows :

1.Cleaning mold

2.Playing off the oil

3.Open material

4.Sprayed

5.Back light

六、产品脱模保养:GRC的产品脱模以后,按照工艺要求,需要保养28天,才可以达到它的最大的强度。一般实际情况下,工厂七天就可以发货。

产品包装运输:出厂的所有的产品,都需要进行良好的包装。首先用包装纸来包装,外部还需要用木卡来进行加固。运输方式一般有陆运和海运两种。如果条件和工期允许,首选海上运输。条件不允许的选择陆运。

六、Product stripping maintenance : GRC products after stripping, in accordance with the process requirements, need to maintain 28 days before they can achieve its maximum strength.Under normal circumstances, the factory can be shipped seven days.

Product packaging Transport : All the products of the factory need to be well packed.First with wrapping paper to packaging, the external also need to use wood to reinforce.There are two kinds of land transport and sea transport.If conditions and duration allow, preferred sea transport. Conditions are not allowed to choose land transport.

-

GRC安装方法详解

GRC installation method in detail一、直接安装法:

直接在建筑原墙上用膨胀螺丝或化学锚栓固定,墙体与产品之间没有其它辅助材料,此法安装方便,快捷,经济。但对建筑本身结构要求非常高,如果空心砖,压气砖等墙体都无法安装,最好是混凝土墙体,另外要求墙体水平垂直精确度比较高,墙平整度比较好。

一、Direct installation method:

Directly in the building wall with expansion screws or chemical anchor bolt, between the wall and the product without other auxiliary materials, this method is easy to install, fast and economical.But the structure of the building itself is very high, if the hollow brick, air brick and other walls can not be installed, preferably the concrete wall, the other requirements of the vertical and horizontal wall accuracy is relatively high, wall flatness is better.

二、明孔安装法:

产品表面预留螺丝孔,孔位须加厚,呈内小外大的形状,安装完的螺丝头不能高于产品表面。

二、Ming Kong installation method:

Product surface set aside the screw hole, hole to be thick, was small outside the shape of large, the installation of the screw head can not be higher than the product surface.

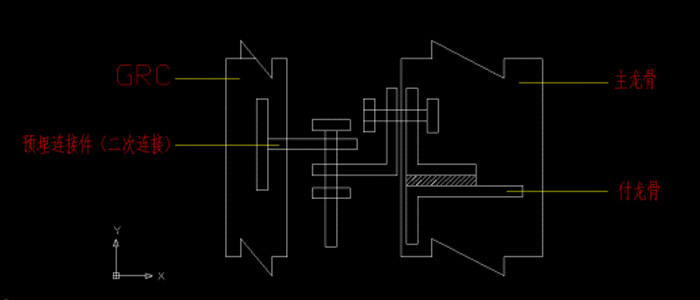

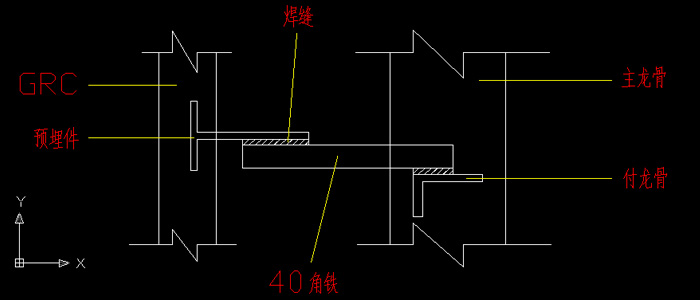

三、钢架龙骨焊接法(干挂式):

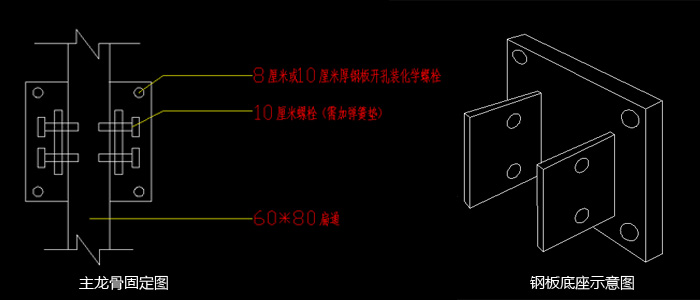

此法适用于产品表面,不再另行喷涂或做其它表面处理的产品。根据产品需要或结构需要一般主龙骨用,60*80*4或40*80*4高通。付骨用50*50*5等边角铁,连接产品处的非关键部件可以用40*40*4等边角铁。具体用料大小根据设计要求,但所用钢材必须为热镀锌螺栓及角码等连接件,可以是不锈钢及热镀锌(起防腐,防锈作用)。主龙骨固定于墙体时应在主体结构的梁位或混凝土墙上生根锚固,见图:

三、Steel frame keel welding method (dry hanging type):

This method applies to the product surface, no longer spray or do other surface treatment products.According to the needs of the product or structure need to use the main keel, 60 * 80 * 4 or 40 * 80 * 4 high-pass.Bone with 50 * 50 * 5 equilateral angle iron, connecting the product at the non-key components can be 40 * 40 * 4 equilateral angle iron.Specific material size according to design requirements, but the use of steel must be hot-dip galvanized bolts and angle code and other connectors, can be stainless steel and hot galvanized (from corrosion, rust effect).When the main keel is fixed in the wall, it should be rooted in the beam or concrete wall of the main structure,See Figure :

主龙骨固定图、钢板底座示意图

Main keel fixed figure, steel base diagram

如出现特殊状况安装于墙体上的底座,基础空鼓没法固定或不牢固,可采用灌浆处理,将墙面开孔,空位用水泥砂浆灌实方可固定锚栓。产品与龙骨间的连接通过锈钢或热镀锌连接件(标准工艺是直接用连接件上螺丝连接,而我们通常为了方便操作会用焊接法,此做法对要求不高的客户还行)。如果烧焊连接的焊接完后的焊缝一定要做防锈防腐处理,且焊缝的长度至少超过连接件的截面的一半长度,不能有虚焊,焊完后应用小尖锤敲击焊接部位以确定焊接牢固。连接件的连链接分为(一次连接和二次连接)如图:

Such as the emergence of special conditions installed on the wall of the base, the basic hollow can not be fixed or not solid, can be used grouting treatment, the wall openings, empty cement mortar can be fixed before the anchor.The connection between the product and the keel is via a stainless steel or hot-dip galvanized connection (the standard process is connected directly to the screw on the connector, and we usually use the welding method for easy operation).If the weld after welding the weld must be done anti-rust anti-corrosion treatment, and the length of the weld at least half of the length of the cross-section of the connector, can not have Weld, welding after the application of small sharp hammer hit welding parts To determine the welding firm.Connection of the link is divided into (one connection and secondary connection) as shown in Figure :

一次连接焊接法示意图

One connection welding method

二次连接焊接法示意图

Secondary connection welding method